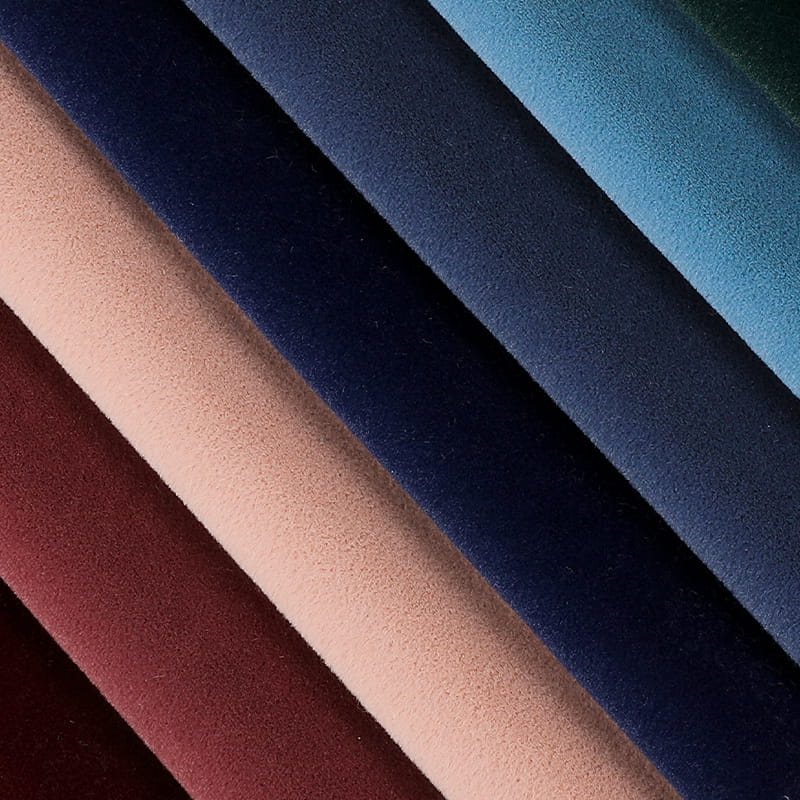

Velvet fabric, known for its rich texture and luxurious feel, has traditionally been associated with high-end fashion and home decor. However, the integration of technology into velvet fabric is pushing the boundaries of what this material can achieve, making it not only a stylish choice but also a functional and innovative one.

Technology velvet fabric is characterized by its short, dense fibers that create a soft, velvety surface. Historically, velvet has been produced through intricate weaving processes, resulting in a fabric that is both visually striking and tactilely pleasing. However, traditional velvet can be prone to wear and tear, limiting its durability and versatility.

Recent technological advancements have addressed these limitations, creating velvet fabrics that are more resilient and adaptable to various applications. Innovations in fiber technology, weaving processes, and surface treatments have allowed manufacturers to produce velvet fabrics that retain their luxurious feel while improving their durability and functionality.

One of the key developments in technology velvet fabric is the use of high-performance fibers. These fibers, such as polyester and nylon, are engineered to be stronger and more durable than traditional cotton or silk-based velvets. They also offer better resistance to fading, staining, and wear, making them ideal for high-traffic areas and outdoor use.

Advancements in weaving techniques have also played a crucial role in the evolution of technology velvet fabric. Modern looms are equipped with computer-controlled systems that allow for precise control over the weaving process, resulting in fabrics with consistent fiber density and uniform appearance. This precision also enables manufacturers to create intricate patterns and textures that were previously impossible to achieve with traditional weaving methods.

Beyond the fiber and weaving innovations, surface treatments and functional finishes have further enhanced the appeal of technology velvet fabric. For instance, anti-microbial treatments can be applied to the fabric to inhibit the growth of bacteria and fungi, making it ideal for healthcare and hygiene-sensitive applications.

Water-repellent and stain-resistant finishes are also popular among consumers, as they protect the fabric from spills and accidents, maintaining its appearance and extending its lifespan. These treatments are often achieved through the application of nanotechnology, which creates a barrier on the fabric surface that repels water and stains while allowing air and moisture to pass through, ensuring breathability and comfort.

The integration of smart textiles and wearable technology is another exciting frontier in the development of technology velvet fabric. By embedding sensors, actuators, and other electronic components into the fabric, manufacturers can create velvet garments and accessories that perform additional functions beyond their traditional aesthetic roles.

English

English Español

Español